Some Known Incorrect Statements About Material Testing Labs

Wiki Article

Get This Report about Material Testing Labs

Table of ContentsMaterial Testing Labs - The Facts7 Simple Techniques For Material Testing LabsNot known Facts About Material Testing LabsThe Basic Principles Of Material Testing Labs Not known Facts About Material Testing LabsThe Best Strategy To Use For Material Testing Labs

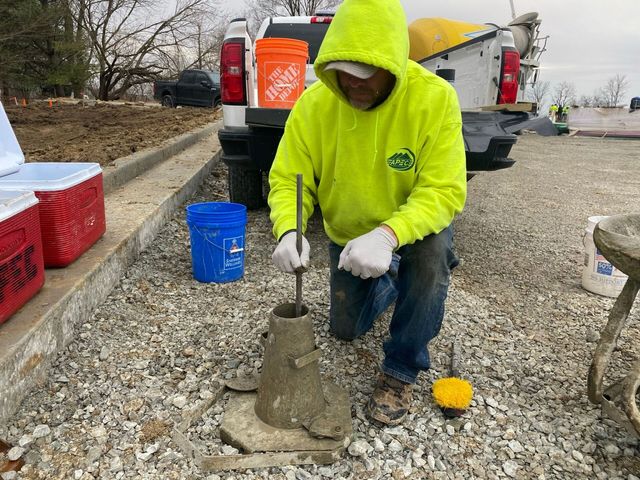

For the compressive strength test, 3 samples from every batch are to be taken. This examination is likewise referred to as the cube examination as the cubes of concrete are applied with tremendous pressure in order to identify the workability, toughness along with the breaking factor of the high toughness mix concrete For the test, the concrete is put right into molds while keeping the appropriate temperature to see to it that there are no feasible voids in the dice of the concrete.Practically all of the shayona concrete in Lilongwe goes through the water leaks in the structure examination. When you are working on a brand-new construction job, whatever framework you are building, the main aim is to make sure that water has to not be able to seep in with the framework as it can disrupt the stamina of the framework.

Besides that of water molecules, chloride ions can additionally disrupt the stamina of the framework if they are enabled to penetrate with the concrete. This examination is conducted on solidified concrete. This examination calls for to keep a voltage across the ends of the concrete cyndrical tube of concerning 60V DC.

Some Known Questions About Material Testing Labs.

While the infiltration of water with high stamina mix concrete need to be stayed clear of in every feasible way, it is likewise crucial to ensure while the concrete is establishing it has to have the ability to soak up a clear-cut quantity of water, this is figured out by the water absorption examination. The inspector appraises the modification in the size of the concrete sample as an outcome of the absorption of water.Hopefully, all the pointers that have been resolved to considerable sizes in this article will certainly provide you with the right set of examinations to carry out for identifying the quality and also stamina of the concrete. High Strength concrete supplied by Insta, Crete goes through all such quality examinations to ensure that you can obtain your hands on concrete which is of remarkable quality.

The concrete blending plant sees to it that the mixing of the concrete happens in an included setting to ensure that the desirable high qualities of the concrete remain undamaged. The online system can present you with high stamina mix concrete at fantastic prices which can be a little little bit challenging to discover someplace else.

Indicators on Material Testing Labs You Should Know

Concrete is just one of one of the most important as well as commonly previously owned materials in the building market. Concrete contains basic materials including cement, sand, aggregates, admixtures, as well as water. All these raw products are blended in a particular percentage to create concrete, according to the requirements. Concrete is widely utilized for the building of aspects like columns, light beams, wall surfaces, lintels, pieces, copings, as well as structures so on.The high quality of concrete must be inspected, preserved, as well as likewise ought to be fixed if the level of quality standards does not match the required degree of top quality. If the top quality of concrete is substandard, it may have an unfavorable effect on the construction. The quality of concrete is inspected in 3 dierent phases of building.

Let us study all the 3 phases of quality assurance of concrete thoroughly. Before the concrete is also prepared, the top quality of raw products shall be checked, and also just then they are blended in a called for proportion to form fresh concrete. The top quality of basic materials is directly related to the top quality of concrete.

The Main Principles Of Material Testing Labs

They are as complies with:- Step -1: Test for top quality of materials made use of in concrete Step 2: different tests on fresh concrete for its high quality check (material testing labs). Concrete is made up of cement, sand, accumulations, and water, specifically. So it is necessary to have a look for the top quality of all of these products.There are a few points which Click Here are very important as well as need to be dealt with to manage the top quality of cement before the beginning of concreting. They are:- Concrete should be evaluated prior to it's included in the concrete mix. The description cement ought to be ultimately examined once every two months. Concrete needs to be maintained away from wetness.

If huge lumps of cement are found in the cement bags, it ought to not be accepted. Accumulations have dierent properties such as shape, size, grades, water absorption, sturdiness, details gravity, etc. All of these residential or commercial properties ought to be inspected for the example of accumulations which are to be utilized while preparing the concrete.

Material Testing Labs Can Be Fun For Anyone

The aggregates must be hard and also strong sufficient to supply proper toughness to toes concrete. If the aggregates are immersed underwater for 24 hrs, the water material need to not surpass 10%.20 mm and 10 mm aggregates will be taken in the proportion of 70:30 or 60:40 to enable far better compaction as well as to attain a higher density of concrete. Some indicate keep in mind while checking the top quality of sand or fine accumulations. Sand used for making concrete this hyperlink will retain on 150-micron screen and also ought to pass 4 (material testing labs).

Indicators on Material Testing Labs You Should Know

Pollutants in water. To ensure the top quality of water, at least 3 dices of concrete need to be cast using that particular sample of water, as well as the compressive stamina of concrete after 28 days must be determined. If the compressive toughness is much less than 90 %, it is advised to reject the sample of water.

Report this wiki page